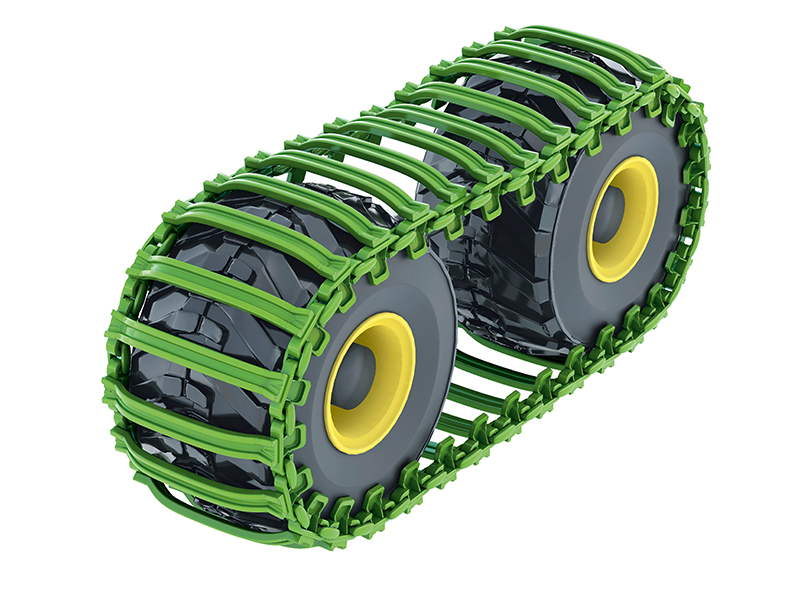

LOGGER Track

To date, about 200 sets of LOGGER tracks are used for sorting logging machines.

Quality control:

Quality control:

Quality control system-step-by-step control of track elements.

Daily quality control of each batch of products according to technical physical and geometric parameters.

Control of the hardness of elements : track, link, C-link, ground hook, shackle of the cross -link- batch control every shift.

Before launching into mass production, we conducted a number of tests of LOGGER tracks in real- world conditions. The tests allowed us to evaluate the performance of tracks when working on different soils and types of terrain, and get feedback from operators. In this way, you can evaluate the performance of the caterpillar in comparison with other brands.

Control of the geometry of elements : track, C-link, shackle of the cross -link- batch control every shift

In addition to the installation instructions, a quality control sheet is attached

Track

Production

In 2018, KMZ introduced a new brand of anti-skid tracks for logging machines-LOGGER.

Specialists of the plant studied the entire technological chain of production of tracks and components for them, which includes everything necessary, starting from the materials of components, all the subtleties of technological processes and the necessary equipment.

Thanks to the accumulated knowledge, we have created lines for the production of track components that have no analogues.

Today we have two lines for the production of tracks, two lines for the production of C-link, as well as lines for the production of links and locks.

To date, we offer the owners of sorting machines anti-skid tracks LOGGER various profiles of tracks, manufactured in strict accordance with all technological processes, from metal cutting to painting.

To date, more than 500 sets of LOGGER tracks are operated by logging companies of the Northwestern Federal District, Volga Federal District, Western Siberia and the Far East.

Specialists of the plant studied the entire technological chain of production of tracks and components for them, which includes everything necessary, starting from the materials of components, all the subtleties of technological processes and the necessary equipment.

Thanks to the accumulated knowledge, we have created lines for the production of track components that have no analogues.

Today we have two lines for the production of tracks, two lines for the production of C-link, as well as lines for the production of links and locks.

To date, we offer the owners of sorting machines anti-skid tracks LOGGER various profiles of tracks, manufactured in strict accordance with all technological processes, from metal cutting to painting.

To date, more than 500 sets of LOGGER tracks are operated by logging companies of the Northwestern Federal District, Volga Federal District, Western Siberia and the Far East.

LOGGER track advantages

Prompt shipment

Prompt shipment to the operating organization , thanks to the presence of dealers in warehouses

Warranty 3000 hours or year of operation

The standard warranty for LOGGER tracks is 3000 hours or a year of operation (other global manufacturers have a warranty of no more than 2500 hours)

Prompt solution

Prompt solution of all issues with the manufacturer, thanks to the customer-oriented track manufacturer LOGGER

Best price

The lowest cost of tracks in cubic meters prepared wood by a sorting complex

Reviews

Leave a request

© 2024 LLC "KMZ"